Anaerobic processes are defined as processes where neither oxygen nor nitrate is present. These processes are carried out by a large and varied group of micro-organisms which normally live in a symbiotic relationship. [1]

Anaerobic digestion has contributed a lot in conservation of natural resources which cannot be replenished back. It involves a series of biological processes which takes place naturally when a bacterium breaks down the organic content in the absence of oxygen.

Anaerobic processes have been used in wastewater treatment systems for more than a century, initially to stabilize the solids produced.[2] These bioreactors, called anaerobic digesters, were simple concrete tanks in which the solids were placed as a slurry and allowed to decompose anaerobically. Hydraulic retention times of 60 days or more were common. Gradually, it was discovered that the decomposition could be accelerated by heating the digester to a consistent temperature of about 35°C and mixing it to provide uniform reaction conditions. These discoveries led to the current high rate anaerobic digestion process, which uses HRTs of 15 to 20 days. Anaerobic digestion remains an extremely popular and widely used solids stabilization process, particularly in municipal wastewater treatment.”[3]

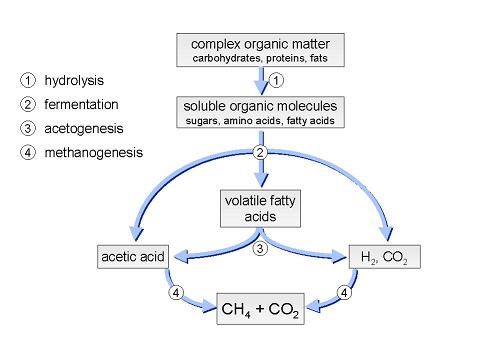

Biological activities have been identified as main root for more than 70% of methane production in the atmosphere. AD is considered to take place in a series of three to four steps namely.

- Hydrolysis

- Acidogenesis (acid forming)

- Acetogenesis

- Methanogenesis

- The rate-limiting reaction in anaerobic digestion is usually the conversion of volatile acids to methane. Methane-forming bacteria obtain very little energy from the degradation of volatile acids. Most of the energy released from the volatile acids is transferred to the methane.Because of the low energy yield obtained from volatile acids by methane-forming bacteria, their growth rate is restricted, that is, the amount of substrate utilization per unit of organisms is high. Therefore, bacterial growth or sludge production is low and optimum operational conditions must be maintained for satisfactory rates of solids destruction and methane production. These factors are responsible for the rate-limiting reaction of the conversion of volatile acids to methane. However, if the substrates fed to the anaerobic digester were mostly slowly degrading particulate materials, then the rate-limiting reaction would be the hydrolysis of the particulate

material.[1]

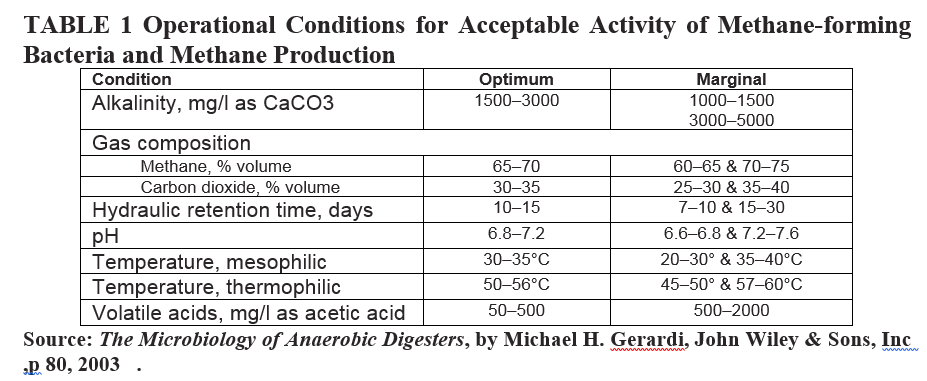

Methane-forming bacteria are strict anaerobes and are extremely sensitive to changes in alkalinity, pH, and temperature. Therefore, operational conditions in the digester must be periodically monitored and maintained within optimum ranges. In addition to alkalinity, pH, and temperature, several other operational conditions should be monitored and maintained within optimum ranges for acceptable activity of methane-forming bacteria. These conditions are gas composition, hydraulic retention time (HRT), oxidation-reduction potential (ORP), and volatile acid concentration (Table 1).

Process control of anaerobic digesters is often difficult, because numerous operational conditions are interrelated and changes in one condition may directly or indirectly affect others. Also, the relatively low concentrations of solids and short solids retention times (SRTs) maintained in completely mixed digesters render the process susceptible to toxic upsets and shock loadings. Another difficulty in achieving proper digester operation is the presence of different bacterial groups that have different optimum values or ranges of values for operational conditions. For example, there are two optimal temperatures for anaerobic digestion of solids.

The acid-forming bacteria have an optimum temperature at 30°C, and the mesophilic, methane-forming bacteria have an optimum temperature at 35°C.

By

Ahmed Ahmed Elserwy

Water & Environmental Consultant

[1] Mogens Henze . Poul Harremoes J es la Cour J ansen . Erik Arvin, Wastewater Treatment, Biological and Chemical Processes , Second Edition, Springer-Verlag Berlin Heidelberg GmbH ,1996.p100.

[2] Malina, J. F., Jr., Anaerobic sludge digestion. In Design of Anaerobic Processes for the Treatment of Industrial and Municipal Wastes, J. F. Malina, Jr. and E G. Pohland. eds. Technomic Publishing, Lancaster, Pennsylvania, pp. 167-21 2, 1992.

[3] U. S. Environmental Protection Agency, Process Design Muttual for Sludge. Trtwtmcwt arid Disposul, EPA 625/1-7!I-O 1 1, U. S. Environmental Protection Agency. (‘incinnati, Ohio, 1979