- Introduction [1]

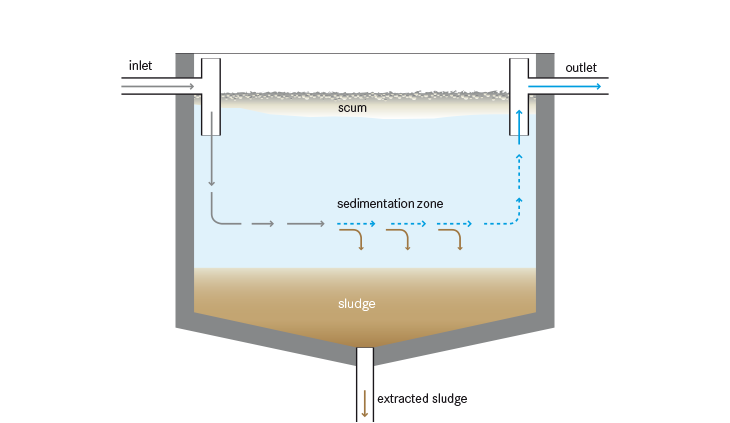

Sedimentation is the physical operation that separates solid particles with a density higher than that of the surrounding liquid. In a tank in which the water flow velocity is very low, the particles tend to go to the bottom under the influence of gravity. As a result, the supernatant liquid becomes clarified, while the particles at the bottom form a sludge layer, and are then subsequently removed with the sludge. Sedimentation is a unit operation of high importance in various wastewater treatment systems.

The main applications of sedimentation in wastewater treatment are:

- Preliminary treatment. Grit removal (sedimentation of inorganic particles of large dimensions)

- Grit chamber

- Primary treatment. Primary sedimentation (sedimentation of suspended solids from the raw sewage)

- Conventional primary clarifiers, with frequent sludge removal

- Septic tanks

- Secondary treatment. Secondary sedimentation (removal of mainly biological solids)

- Final sedimentation tanks in activated sludge systems

- Final sedimentation tanks in trickling filter systems

- Sedimentation compartments in anaerobic sludge blanket reactors

- Sedimentation ponds, after complete-mix aerated lagoons

- Sludge treatment. Thickening (settling and thickening of primary sludge and/or excess biological sludge)

- Gravity thickeners

- Physical–chemical treatment. Settling after chemical precipitation

- Enhancement of the performance of primary clarifiers

- Polishing of effluents from secondary treatment

- Chemical nutrient removal

- Physical–chemical treatment (chemical coagulation) of mainly industrial wastewater, but also domestic wastewater

Besides these, sedimentation occurs in various other wastewater treatment units, such as stabilisation ponds, even if they have not been specifically designed for this purpose.

The main objective in most of the applications is to produce a clarified effluent, that is, with a low suspended solids concentration. However, at the same time it is also frequently desired to obtain a thickened sludge to help its subsequent treatment.

Plain sedimentation is usually employed in wastewater treatment, whereas in water treatment plants, sedimentation, in most cases, is preceded by chemical coagulation. [2]

Sedimentation is also employed, to a limited scale, in separating particulates from air streams.

- Significance of Sedimentation in Water and Wastewater Treatment [2]

Sedimentation is a major unit operation that is employed at almost every water- and wastewater-treatment plant. In water purification plants the turbidity of water must be reduced to levels as low as possible. Usually a turbidity of 1.5 units is considered desirable for water introduced into filters. This is achieved either by plain sedimentation or by coagulation followed by sedimentation. Plain sedimentation usually requires a long time to be effective in water-treatment operations, so chemicals are added to induce floc formation and the flocs then settle rapidly. At a wastewater-treatment plant, sedimentation in the primary settling tank reduces the load on subsequent treatment units.

Sedimentation in secondary settling tanks is most important as it removes a large percentage of the suspended solids from the treated wastewater, which would otherwise be carried into the effluent and then into the streams to which the effluent is usually discharged.

Sedimentation in sludge thickeners is also very important in reducing the amount of water retained by sludge. As sludge is thickened, its volume is reduced considerably, with the result that a smaller sludge digester or less sludge dewatering equipment is required. For example, a 1% sludge thickened to 3% would occupy approximately one third of the original volume, thereby reducing the sludge to be handled by over 66%.

- Theory of Sedimentation

All particles suspended in a fluid of lower density tend to settle under the influence of gravity. Table 1 lists the settling velocities of suspended particles in still water. The rate of settling depends on the shape, size, and specific gravity of the particles, as well as the viscosity, temperature, and quiescence of the liquid.

Coarse and heavy particles settle rapidly and can be removed by storage in large tanks. Fine particles, 10 μm or less in diameter and with a density a little above that of water, cannot be economically removed by sedimentation alone. These particles require coagulation by the addition of chemicals to increase the effective particle size, which results in an increased rate of settling.

In the field of environmental engineering, the principles of sedimentation are applied in both water and wastewater treatment. In the treatment of surface waters, sedimentation is employed after coagulation and before filtration. In the treatment of wastewater, sedimentation principles are employed in the design of grit chambers, primary settling tanks, secondary or final settling tanks, and gravity sludge thickeners.

Table 1

Settling Velocities of Suspended Particles in Water (a)

| Diameter of particle (μm) | Approximate time required to settle 1 m | Typical material |

| 10.000 | 1.2 s | Gravel |

| 1000 | 9 s | Coarse sand |

| 100 | 2 min | Fine sand |

| 10 | 2 h | slit |

| 1 | 6 d | Bacteria |

| 0.1 | 800 d | Clay particles |

| 1.01 | 250 yr | Color bodies |

(a ) Temperature 10oC, spherical particles, specific gravity = 2.65, same chemical characteristics, quiescent conditions.

- General Consideration and Basis of Design for Sedimentation tank [3]

Sedimentation is applied in wastewater treatment in three different kinds of tanks.

These are primary sedimentation tanks, secondary or final sedimentation tanks, and gravity thickeners for sludge concentration. Although the theory of sedimentation is the same in both water and wastewater treatments, sedimentation in wastewater treatment differs from that in water treatment in the following aspects:

- More suspended solids in wastewater.

- Wastewater suspended solids are usually of lower specific gravity.

- Size of particles is larger.

- Normally no chemicals are employed.

- Effluent from wastewater sedimentation tanks usually contains more suspended solids than that from water sedimentation tanks.

- Sludge has to be removed continuously to prevent septic condition.

- Types of settling Tanks [4]

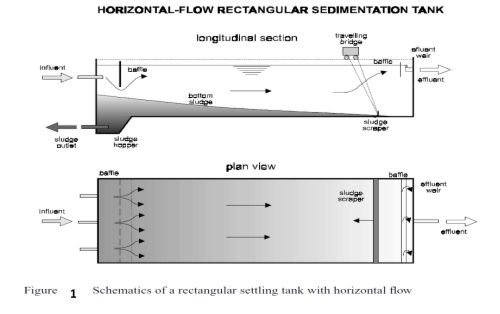

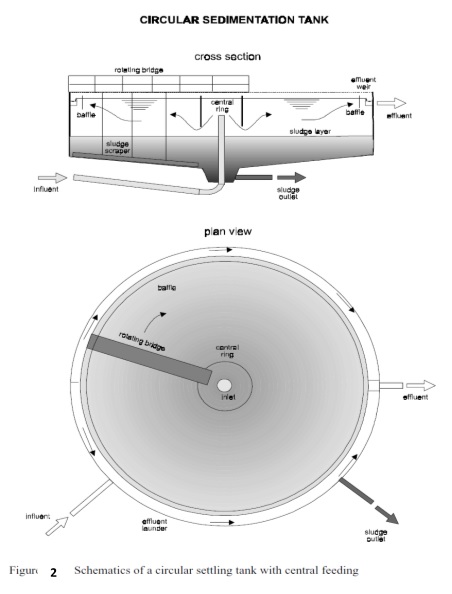

Figures 1 and 2 present the schematics of two types of settling tanks, one rectangular with horizontal flow, and the other circular with central feeding. Details about the design of these settling tanks are presented in the relevant chapters of this book, related to the various wastewater treatment processes. In the present chapter, only the basic principles of sedimentation are presented.

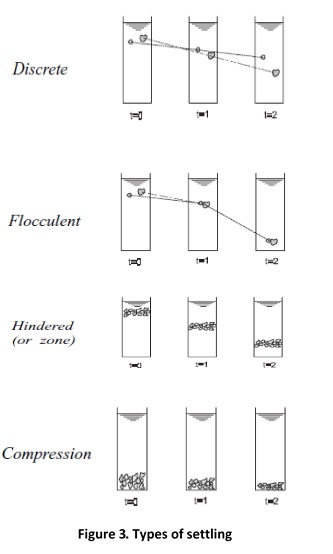

7.Types of Settling

In wastewater treatment, there are basically the four different types of settling described in Table2. It is probable that during a settling operation more than one type occurs at a given time.

Table 2. Settling types in wastewater treatment

| Type | Description | Example of application/ Occurrence |

| Discrete | The particles settle,

maintaining their identity, that is, they do not coalesce. Hence, their physical properties such as shape, size and density are preserved. |

• Grit chambers |

| Flocculent | The particles coalesce

while settling. Their characteristics are changed, with an increase in size (floc formation) and, as a result, in the settling velocity. |

• Primary sedimentation tanks

• Upper part of secondary sedimentation tanks • Chemical flocs in physical–chemical treatment |

| Hindered

(or zone) |

When there is a high

concentration of solids, a sludge blanket is formed, which settles as a single mass (the particles tend to stay in a fixed position with relation to the neighbouring particles). A clear separation interface can be observed between the solid phase and the liquid phase. The interface level moves downwards as a result of the settling of the sludge blanket. In this case, it is the settling velocity of the interface that is used in the design of the settling tanks. |

• Secondary

sedimentation tanks • Sludge gravity thickeners |

| Compression | If the solids concentration

is even higher, the settling could occur only by compression of the particles’ structure. The compression occurs due to the weight of the particles, constantly added because of the sedimentation of the particles situated in the supernatant liquid. With the compression, part of the water is removed from the floc matrix,reducing its volume |

• Bottom of secondary

sedimentation tanks • Sludge gravity thickeners |

| Source: adapted from Tchobanoglous and Schroeder (1985), Metcalf and Eddy (1991) | ||

By

Ahmed Ahmed Elserwy

Water & Environmental Consultant

Ain Shames University, Faculty of Science

References

[1] Marcos von Sperling ,2007. Basic Principles of Wastewater Treatment ,IWA Publishing, London, UK,page 125.

[2] Lawrence K. Wang, Physicochemical treatment processes, Humana Press Inc, Totowa, New Jersey 0751,2004.

[3] Lawrence K. Wang, Physicochemical treatment processes, Humana Press Inc, Totowa, New Jersey 0751,2004 , p 394.

[4] Marcos von Sperling ,2007. Basic Principles of Wastewater Treatment ,IWA Publishing, London, UK,page 127.