1. Wastewater Characteristics

Wastewater is another term for sewage; water that has been used in homes, industries, institutions, and businesses that is not for reuse and is generally collected in a sewage collection or drainage system .In general, raw wastewater is 99.9% water and 0.1% impurities.

However, the impurities in wastewater can cause damage to our environment, create odors and pose significant risks to human health, if the wastewater is not treated properly.

Organic matter comprises approximately 75% of the impurities in wastewater; it is predominantly human and food waste.

Nitrogen, phosphorus and trace levels of other nutrients are present in wastewater. Nutrients encourage plant growth that can generate excessive plant and algae growth in water and can be detrimental to the natural ecosystem. Therefore, it is essential that excessive nutrients be removed from the water source prior to disposal.

Industrial wastewater may have toxic elements that must be removed prior to discharge. The main concerns are heavy metals, organic compounds, oils and fats.

Heavy metals including arsenic, cadmium, cobalt, chromium, copper, iron, lead,manganese, nickel and zinc can be found in wastewater .Most of the metals are removed in the treatment process and end up in the solids. Therefore, most heavy metal concerns deal with the disposal or reuse of the sludge.

All wastewater contains microorganisms that are beneficial to wastewater processing and others that can be harmful.

Aerobic and anaerobic bacteria carry out decomposition of the organic matter into more stable forms that are more easily disposed of in the environment.

Pathogens are microorganisms that can cause disease in plants, animals and humans. The processed water is disinfected prior to discharge to kill microorganisms that may be detrimental to the ecosystem.

- Wastewater Collection

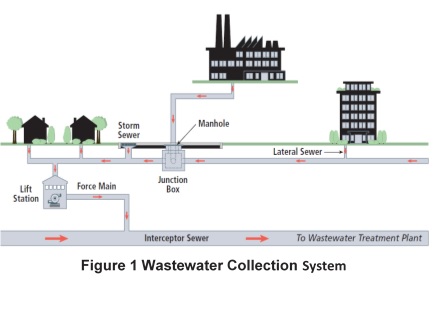

The wastewater treatment process begins with the collection of waste streams from homes, businesses and industrial complexes.

These streams feed into what is known as the “collection” or “drainage” system which transports the wastewater to the wastewater treatment plant for processing. The collection system is typically operated as a separate department within the municipality.

The collection system is comprised of pipes, junction boxes, lift stations and associated equipment that channel raw wastewater to the plant. In many cases, the collection system

will also serve to collect storm run off. Systems that convey storm run off and waste streams are known as combined sewer overflow (CSO) systems.

Individual homes are connected to the collection system through a lateral sewer to the main sewer line. Sewer lines come together from different directions into a junction box.

Junction boxes combine the flow from main lines into a much larger flow heading towards the wastewater treatment plant.

Wherever possible, the design of the collection system and the location of the facility will utilize gravity to move the wastewater to the wastewater treatment plant. However,

where this is not feasible, because of the municipality’s location, elevation changes and system design, lift stations will be used to pump the wastewater to the plant.

The size and pumping capacity of each lift station will be dependent on the maximum estimated flow rates at each station. Where flow rates are relatively low, lift stations are quite small and will typically have two small submersible pumps to move the stream. As the collection system gets closer to the treatment plant, flow rates will increase. Lift stations closer to the plant can become quite large, requiring several large capacity pumps to provide adequate flow capacity.

All lift station designs must consider flow rate changes due to demand variations, such as the time of day and storm surges.

People take showers in the early morning, which corresponds with the highest daily flow rates a treatment facility experiences.

If the collection system is configured for CSO, there may be a series of large auxiliary storm pumps in these pumping stations.

From the collection system, the wastewater enters the Wastewater Treatment Plant.

- Wastewater Processing

A Wastewater Treatment Plant (WWTP) is a facility designed to receive the wastewater from primarily domestic, commercial, and industrial sources and to remove materials that damage water quality and threaten public health and safety when discharged into receiving streams or bodies of water.

Most facilities employ a combination of mechanical removal steps and bacterial decomposition to achieve the desired results. Chlorine is often added to discharges from the plants to reduce the danger of spreading disease by the release of pathogenic bacteria.

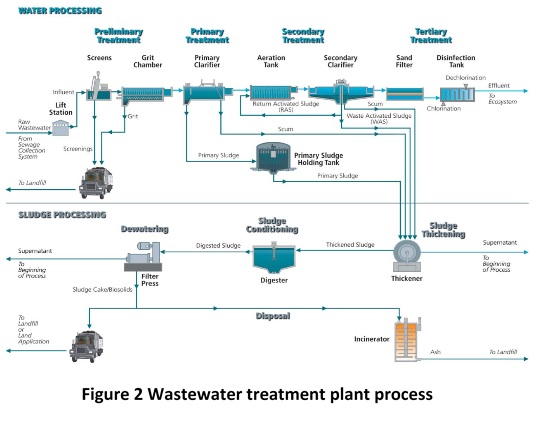

Figure 2 illustrates the processes of a typical wastewater treatment plant. The top half illustrates the Water Processing flow chart. Raw wastewater is pumped to the wastewater treatment plant through lift or pumping stations.

Lift stations are required when a sewage system serves a community or area lower than the plant, where an uphill shortcut will significantly decrease the total length of pipe required to tie into the plant, or where existing structures or other constraints require an uphill route to the WWTP.

The wastewater enters the plant at the head works where processing starts.

The typical water processing steps include:

- Preliminary Treatment

- Primary Treatment

- Secondary Treatment

- Tertiary Treatment

Preliminary Treatment

The head works include the influent channel, coarse and fine screens and aerated grit chambers where preliminary treatment occurs. Flow measurement, screening, pumping, and

grit removal are the typical steps in preliminary treatment.

Wastewater enters the influent channel into the coarse screens. The screens remove large debris that enters the sewage collection system such as rags, tramp metal, sticks, broken glass, rocks, sand and the vast variety of other materials.

Screens are utilized early in the wastewater treatment process to minimize pump and equipment damage within the facility. In many wastewater treatment plants, fine screens are utilized to remove smaller debris. All screened debris is removed and disposed as landfill.

The wastewater is then pumped into grit removal chambers. Air is introduced into the chamber to scour the organic materials from the grit before the grit settles to the bottom of the chamber. The settled grit or sand is delivered by a screw conveyor to a pit at one end of the chamber. From there, it is pumped by a grit pump to a grit/water separator .This debris

is also disposed as landfill. Liquid separated from the grit is returned to the grit chamber. Wastewater from the grit chamber then flows to the primary clarifiers.

Primary Treatment

The primary treatment process reduces the solids content of wastewater through sedimentation. Wastewater slowly flows into large tanks called primary clarifiers where heavier particles are allowed to settle at the bottom of the clarifier. Scrapers move the settled solids (primary sludge) to sumps at one end of the clarifier. From there, the primary sludge is pumped into a holding tank where solids processing commence.

Solids lighter than water float to the top and are skimmed from the top of the primary clarifier and pumped to a thickener for solids processing. The greases and fats skimmed from the top of the clarifier are called scum. Primary treatment removes approximately 30 – 50% of the suspended solids. The remaining clarified liquid, containing mostly dissolved materials, flows to the secondary treatment stage.

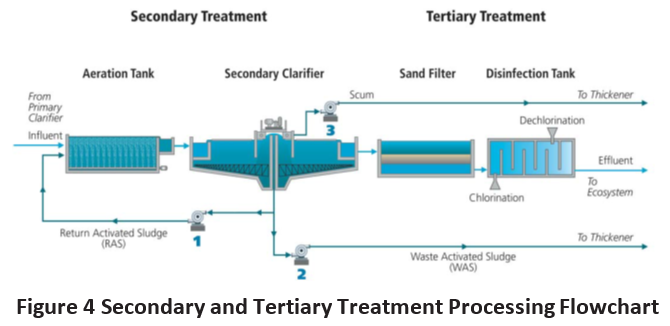

Secondary Treatment

During secondary treatment, organic material is removed through biological treatment. The most widely used biological treatment method is the activated sludge process. The activated sludge process requires an aerated tank containing bacteria that break down the organic materials. The bacteria use the organic material in the liquid and clump together to

form a microbial floc, which is also known as activated sludge. This liquid flows into the secondary clarifiers where the activated sludge is allowed to settle. In some wastewater treatment plants, ferric chloride is added after biological treatment to cause precipitation of phosphate materials remaining in the liquid.

Flow enters the clarifiers from the bottom of the tank through a pipe located at the center of the tank. The clarifiers are designed to direct the flow from the center of the clarifier in a downward direction to encourage the solids to settle. The activated sludge settles at the bottom of the secondary clarifier.

Some of the settled activated sludge is collected and is returned to the aeration tank to insure sufficient bacteria and organic waste supply to maintain the biological process. This material is called Return Activated Sludge (RAS).The activated sludge not needed for the biological process is called Waste Activated Sludge (WAS) and will be pumped to the sludge conditioning stage for further processing.

The clarified liquid, with over 95% of the organic materials removed, flows to the tertiary treatment stage. Scum, formed on the top of secondary clarifiers is sent to a thickener for solids processing.

Tertiary Treatment

The tertiary treatment stage normally starts with the filtering of the clarified liquid that flows from the secondary clarifiers. The liquid is processed through a bed of sand or other filtering device that removes additional pollutants from the liquid.

The water then moves to the disinfection tank. Water enters the disinfection tank where chlorine gas or sodium hypochlorite is metered in the tank. The water slowly moves through the tank to enable the chlorine to kill the microorganisms remaining in the wastewater that may be harmful to fish life. The disinfected water is then passed on to a dechlorination stage to remove the chlorinated materials that also could be harmful to fish life. Sulfur dioxide or sodium metabisulfate are the most cost effective chemicals utilized to neutralize chlorine.

Another disinfection method that eliminates a dechlorination stage is called ultraviolet disinfection. Ultraviolet light sources are submerged in a holding tank. The ultraviolet lamps emit radiation that penetrates the cell wall of the microorganism and is absorbed by cellular materials, which either prevents replication or causes death of the cell. As a result, pathogenic microorganisms are almost entirely inactivated or killed .The UV light disinfection technology is considered to have no adverse environmental impact.

The water or effluent can now be discharged into the ecosystem.

- Wastewater sludge

When wastewater is treated using various mechanical, biological, and physiochemical methods to remove organic and inorganic pollutants to levels required by the permitting authority, the sludge produced will also vary in quantity and characteristics from one treatment plant to another.

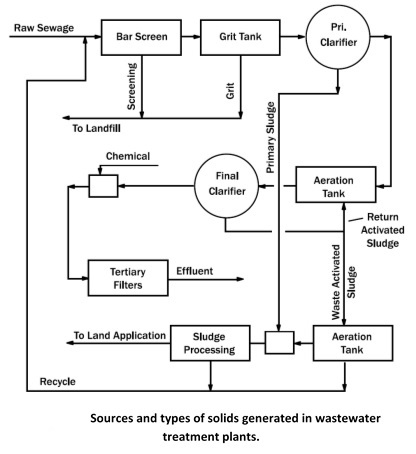

4.1Types of sludge

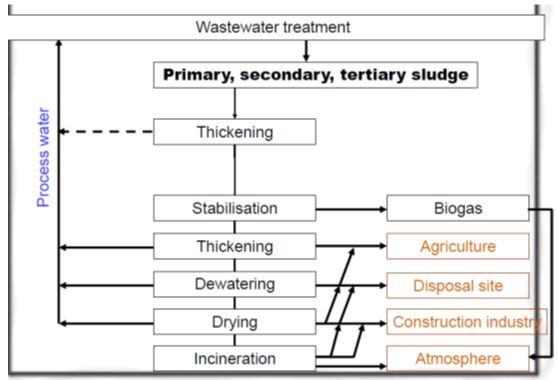

Types of sludge and other solids, such as screenings, grit, and scum, in a wastewater treatment plant vary according to the type of plant and its method of operation. The sources and types of solids generated in a treatment plant with primary, biological, and chemical treatment facilities are illustrated in Figure 5.

Wastewater sludge can be classified generally as primary, secondary (also called biological), and chemical. Sludge contains settleable solids such as (depending on the source) fecal material, fibers, silt, food wastes, biological flocs, organic chemical compounds, and inorganics, including heavy metals and trace minerals. The sludge is raw sludge when it is not treated biologically or chemically for volatile solids or pathogen reduction. When the sludge is treated, the resulting biosolids can be classified by the treatment, such as aerobically digested (mesophilic and thermophilic), anaerobically digested (mesophilic and thermophilic), alkaline stabilized, composted, and thermally dried. The treated sludge can be only primary, secondary, or chemical, or a mixture of any two or three of the sludge’s.

4.1.1 Primary Sludge

Most wastewater treatment plants use the physical process of primary settling to remove settleable solids from raw wastewater. In a typical plant with primary settling and a conventional activated sludge secondary treatment process, the dry weight of the primary sludge solids is about 50% of that for the total sludge solids. The total solids concentration in raw primary sludge can vary between 2 and 7%. Compared to biological and chemical sludges, primary sludge can be dewatered rapidly because it is comprised of discrete particles and debris and will produce a drier cake and give better solids capture with low conditioning requirements. However, primary sludge is highly putrescible and generates an unpleasant odor if it is stored without treatment.

4.1.2 Secondary Sludge

Secondary sludge, also known as biological sludge, is produced by biological treatment processes such as activated sludge, membrane bioreactors, trickling filters, and rotating biological contactors. Plants with primary settling normally produce a fairly pure biological sludge as a result of the bacteria consuming the soluble and insoluble organics in secondary treatment system. The sludge will also contain those solids that were not readily removed by primary clarification. Secondary sludge generated in plants that lack primary settling may contain debris such as grit and fibers. Activated sludge and trickling filter sludge generally contain solids concentrations of 0.4 to 1.5% and 1 to 4%, respectively, in dry solids weight. Biological sludge is more difficult to dewater than primary sludge because of the light biological flocs inherent in biological sludge.

4.1.3 Chemical Sludge

Chemicals are used widely in wastewater treatment, especially in industrial wastewater treatment, to precipitate and remove hard-to-remove substances, and in some instances, to improve suspended solids removal. In all such instances, chemical sludges are formed. A typical use in removing a substance from wastewater is the chemical precipitation of phosphorus. The chemicals used for phosphorus removal include lime, alum, and “pickle liquors” such as ferrous chloride, ferric chloride, ferrous sulfate, and ferric sulfate. Some treatment plants add the chemicals to the biological process; thus, chemical precipitates are mixed with the biological sludge. Most plants apply chemicals to secondary effluent and use tertiary clarifiers or tertiary filters to remove the chemical precipitates. Some chemicals can create unwanted side effects, such as depression of pH and alkalinity of the wastewater, which may require the addition of alkaline chemicals to adjust these parameters.

4.1.4 Other Wastewater Residuals

In addition to sludge, three other residuals are removed in wastewater treatment process: screenings, grit, and scum. Although their quantities are significantly less than those of sludge in volume and weight, their removal and disposal are very important.

Screenings include relatively large debris, such as rags, plastics, cans, leaves, and similar items that are typically removed by bar screens. Quantities of screenings vary from 4 to 40 mL/m3 (0.5 to 5 ft3/MG) of wastewater. The higher quantities are attributable to wastes from correctional institutions, restaurants, and some food-processing industries. Screenings are normally hauled to a landfill. Some treatment plants return the screenings to the liquid stream after marcerating or comminuting. This is not recommended because many of the downstream pieces of equipment, such as mixers, air diffusers, and electronic probes, are subject to fouling from reconstituted rags and strings.

Grit consists of heavy and coarse materials, such as sand, cinders, and similar inorganic matter. It also contains organic materials, such as corn, seeds, and coffee grinds. If not removed from wastewater, grit can wear out pump impellers and piping. Grit is typically removed in grit chambers. In some treatment plants, grit is settled in primary clarifiers along with primary sludge and then separated from the sludge in vortex-type grit separators. The volume of grit removed varies from 4 to 200 mL/m3 (0.5 to 27 ft3/MG) of wastewater. The higher quantities are typical of municipalities with combined sewer systems and sewers that contribute excessive infiltration and inflow.

Grit is almost always landfilled.

Scum is the product that is skimmed from clarifiers. Primary scum consists of fats, oils, grease, and floating debris such as plastic and rubber products.

It can build up in piping, thereby restricting flow and increasing pumping costs, and can foul probes, flow elements, and other instruments in the waste stream. Secondary scum tends to be mostly floating activated sludge or biofilm, depending on the type of secondary treatment used. The quantity and moisture content of scum typically are not measured. It may be disposed of by pumping to sludge digesters, concentrating, and then incinerating with other residuals, or drying and then landfilling.

- Sludge Processing

The purpose of primary and secondary treatment is to remove as much organic solids from the liquid as possible while concentrating solids in a much smaller volume for ease of handling and disposal. Primary sludge has a typical solids content of 4 – 6%. Sludge processing reduces the solids content of this sludge through biological processes and removes more of the liquid content of it prior to disposal.

The overall sludge processing investment cost at the typical wastewater treatment plant is about one-third of the total investment in the treatment plant. However, based on the individual wastewater treatment plant’s processing system, operating expenses in sludge processing typically amount to even a larger portion of the total plant operating costs. To reduce plant operating costs, it is essential to have a properly designed and efficiently operated sludge processing stage.

The design options for each process will be dependent on the type, size, and location of the wastewater treatment plant, and the solid disposal options available. The design must be able to handle the amount of sludge produced and converted economically to a product that is environmentally acceptable for disposal.

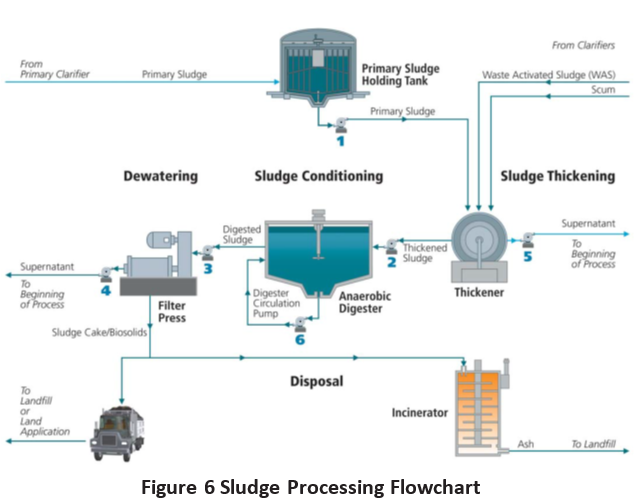

As with water processing, sludge process methods will be determined by the specific constraints and requirements of the individual wastewater treatment plant. Our schematic

covers the general processing steps found in a typical plant.

There will be many plant-to-plant variations that are not illustrated in our article highlights the processes of a typical wastewater treatment plant. The bottom half illustrates the Sludge Processing flowchart.

The typical sludge processing steps include:

- Sludge Thickening

- Sludge Conditioning

- Dewatering

- Disposal

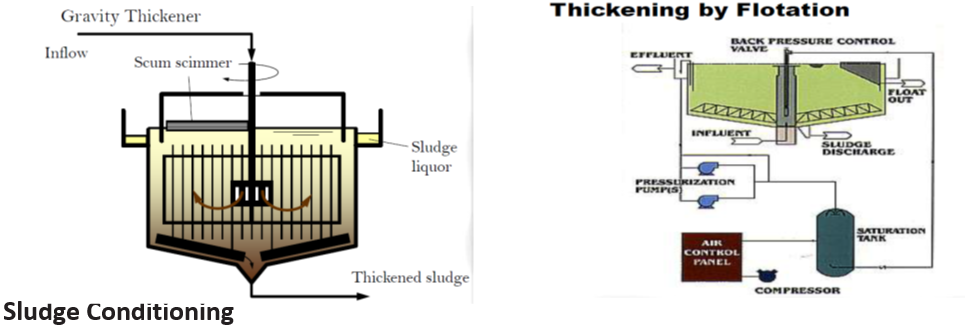

Sludge Thickening

To optimize the sludge conditioning stage, it is important to maximize the solids content of the materials decanted from the water processing stages. The waste activated sludge, scum, and primary sludge can be thickened to reduce the liquid content prior to sludge conditioning. Due to the varying physical nature and liquid content of these materials, facilities may use different thickening processes and equipment for these three materials. In some cases, the primary sludge may not even be thickened and will be pumped directly to

sludge conditioning.

The intent is to optimize the downstream processing capabilities.

The four most common thickening methods include gravity settling, gravity belt thickening, dissolved air flotation, and centrifuge thickening.

The recovered liquid or supernatant from thickening is pumped back into the aeration tank or to the beginning of the water processing stage and is reprocessed.

Sludge Conditioning

Sludge conditioning is a key stage in the reduction of solids prior to disposal. Based on the size and location of the facility five common methods are typically utilized; chemical

treatment, anaerobic digestion stabilization, aerobic digestion stabilization, lagoon storage, and heat treatment.

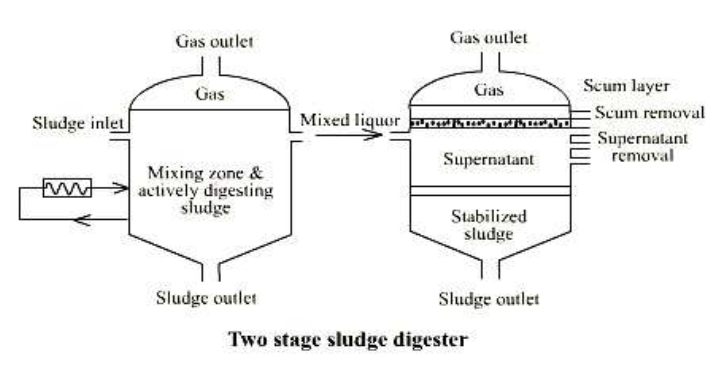

Many facilities will have some type of aerobic or anaerobic digestion stage prior to dewatering. The purpose of sludge digestion is to convert bulky odorous sludge into a relatively inert material that can be rapidly dewatered without obnoxious odors.

Thickened waste activated sludge, scum, and primary sludge are pumped into the digester. In anaerobic digestion, the digester uses the naturally occurring anaerobic microorganisms

to break down organic materials into methane and carbon dioxide gases.The sludge is heated to 37°C (100°F) and agitated continuously in the digester to improve the rate of digestion.

There are two different anaerobic processes, single stage and two-stage. Single stage digesters utilize one digester (tank) to digest the sludge, capture methane gas and store the sludge until it is transferred to the dewatering process

Two-stage anaerobic digestion uses a primary and secondary digester. The primary digester is heated and utilizes mixers to completely agitate the sludge, which maximizes sludge digestion. The secondary digester is not agitated and is utilized for gravity thickening and storage of the digested sludge. The secondary digester typically incorporates a floating

gas dome for methane gas collection and supernatant is pumped out to increase solids content.

Anaerobic digestion is a biological process that breaks down a significant amount of organic solids in the sludge and produces methane gas that is utilized as a fuel for the plant.

Consequently, the volume of final sludge is greatly reduced, which in turn reduces the cost for sludge disposal.

The process also reduces the level of pathogenic microorganisms enabling digested sludge to be classified as biosolids that can be utilized as a soil conditioner or fertilizer.

Sludge can also be stabilized by long-term aeration that biologically destroys volatile solids. An aerobic digester is normally operated by continuously feeding raw sludge with intermittent supernatant and digested sludge withdrawals.

The digested sludge is continuously aerated during filling and for the specified digestion period after the tank is full.

Aeration is then discontinued to allow the stabilized solids to settle by gravity. Supernatant is decanted and returned to the head of the treatment plant, and a portion of the gravity thickened sludge is removed for dewatering.

The next step for the stabilized sludge is dewatering.

Dewatering

Dewatering is the final stage prior to sludge disposal. The goal is to economically remove as much liquid as possible from the sludge or digested sludge prior to disposal. The most common method of dewatering utilizes a belt filter press. The belt filter press has two continuous porous belts that pass over a series of rollers to squeeze water out of the sludge that is compressed between the two belts. Polymers are typically added to the process to enhance dewatering capabilities. Centrifuges are also used for dewatering, typically, in larger wastewater treatment plants.

Any supernatant that is removed in the dewatering process is returned to the beginning of the treatment plant for reprocessing.

Disposal

Digested sludge that is processed into biosolids can be used to spread on farmland as a soil conditioner or can be further processed as fertilizer. It can also be disposed as landfill.

Sludge can also be incinerated and the remaining ash is disposed as landfill. Economics and environmental regulations will be the primary drivers in what disposal method an individual wastewater treatment plant uses.

By

Ahmed Ahmed Elserwy

Water & Environmental Consultant

Ain Shames University, Faculty of Science

References

METCALF & EDDY (1991). Wastewater engineering: treatment, disposal and reuse.

.