Introduction [1]

Flotation may be used in lieu of the normal clarification by solids-downward-flow sedimentation basins as well as thickening the sludge in lieu of the normal sludge gravity thickening. Water containing solids is clarified and sludges are thickened because of the solids adhering to the rising bubbles of air. The breaking of the bubbles as they emerge at the surface leaves the sludge in a thickened condition.

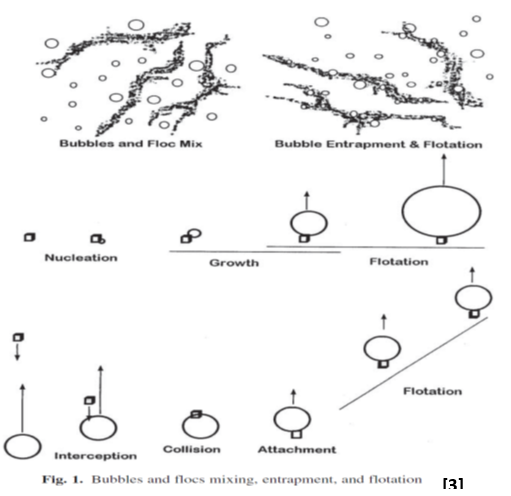

In a flotation system for solid/liquid separation, there are at least two methods by which gas bubbles can be used to increase the buoyancy of suspended solids: (a) entrapment of the bubbles in the particle structure; and (b) adhesion of the bubbles to the particle surface (see Fig. 1). In the former case, as the gas bubbles rise toward the surface, the controlled turbulence in the inlet compartment causes contact between the solids.

The floc, formed by the natural floc-forming properties of the materials or by the chemicals

that have been added, increases in size because of more contact with other solids.

Eventually, a structure is formed that does not permit rising gas bubbles to pass through or around it. [2]

What is a DAF?

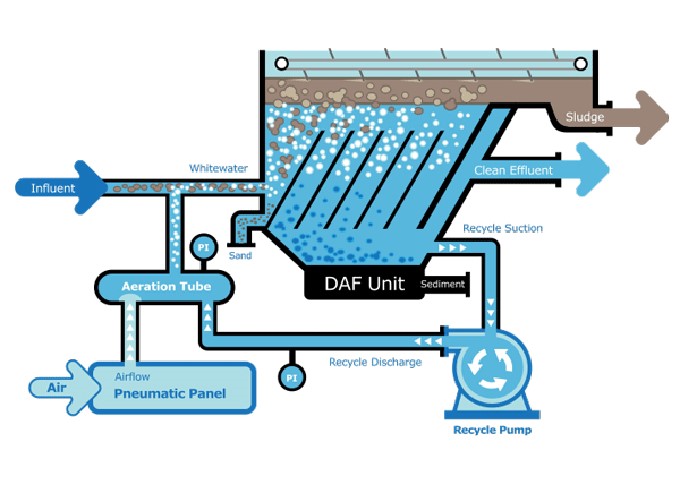

Dissolved air flotation (DAF) is a water treatment process that clarifies wastewater by removing suspended solids. The removal is achieved by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it is then removed by a skimming device. Chemicals can be added to the feed water to improve solids removal.

Where and why are DAFs used?

DAFs are widely used in treating industrial wastewater effluents from oil refineries, chemical plants and paper mills to the food & beverage industries. DAFs are used to removed suspended solids, such as Total Suspended Solids (TSS), Fats, Oil & Grease (FOG) and other pollutants from wastewater so that the water is suitable for re-use or discharge to a wastewater treatment facility.

How does a DAF work?

Wastewater is fed into a DAF system and hit with a stream of “whitewater”, which is recirculated clarified water from the DAF that’s super saturated with dissolved air. As these two mixtures blend together, microscopic bubbles attach to solid particulates, giving them enough buoyancy to surface in the DAF tank.

As solids accumulate in a floating layer on the top of the DAF tank, a skimmer gently nudges the sludge toward a discharge hopper.

Any solids that don’t float will sink to the “V” bottom of the DAF tank. Settled solids are concentrated and discharged by an automatically controlled pneumatic drain valve.

The clarified water flows out via an under-over weir on either side of the DAF unit. Some of this water is used in the recirculation loop while the rest flows out of the vessel.

What are Common Types of DAFs?

- Open Tank

Open Tank DAFs are ideal for treating wastewater that is heavily loaded with solids. This type of wastewater requires significant amounts of free surface area for flotation and separation. Open tank DAFs are normally rectanglar in shape and are built wider and longer as the free separation area requirement increases.

- Plate Pack

Plate Pack DAFs are characterized by high-built (tall) tanks with inclined, corrugated plate packs. Water is introduced into the plate packs in a cross-flow configuration, reducing the distance solids have to float to be effectively separated. As they collide with an angled plate, light solids accelerate upward and heavy particles settle. Wastewater enters the plate pack heavily laden with flocculated contaminants and exits devoid of suspended and colloidal solids.

Which DAF Type is Right for My Application?

Generally speaking, a plate pack DAF unit is suited for high hydraulic and low solids loading rates. Open style DAF tanks are better suited for high solids loading rates.

But before we go and place plate pack DAFs and open tank DAFs into specific applications or industries, let’s understand one concept: anywhere you can use a plate pack DAF unit, you can also use an open tank DAF unit, but the opposite does not hold true. Similar to the rule that says, “a square is a rectangle, but a rectangle is not a square.” The trade off for always going with an open style tank is the amount of floor space they occupy, and their overall cost, especially as flow rates rise above a few hundred gallons per minute.

What are Common Components of a DAF?

Flotation Tank

The Flotation Tank is where the water separates from pollutants. The water is flowing through the flotation tank at a slow speed, giving time for heavy objects to settle down and lighter objects to float up to the top with help from bubbles and flocculators. The flotation tank can vary in depth, width and length based on the application and the time needed for pollutants to be removed.

The Dewatering Grid is a rectangular framework of angular steel plates that lock sludge in place as it rises to the surface. Only when sludge has thickened enough to rise above the top edge of the grid can it be skimmed and pushed to the float hopper.

The Dewatering Grid helps:

- Operators control sludge thickness

- Eliminate pre-mature removal of solids

- Reduce build-up and/or re-entrainment of sludge

- Generate drier sludge

Skimmers

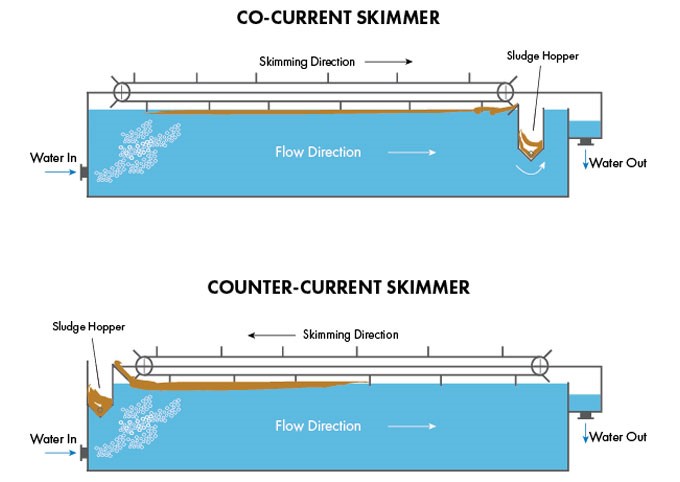

While many DAF system designs push sludge across the entire length of the tank in the same direction as the wastewater flow called a Co-Current Skimmer, another design uses a skimmer assembly that rotates against the hydraulic flow of the water called a Counter-Current Skimmer. The Counter-Current Skimmer design shortens the sludge skimming distance and eliminates solids carry-over.

Flocculators are designed to provide the mixing action and retention time required to adequately coagulate and flocculate solids in wastewater to improve solids removal.

DAF pumps are a key component of all DAF Systems. On it rides some of the largest capital, operations and maintenance expenses involved in wastewater pre-treatment systems.

DAF manufacturer’s approach recycle pumps in two different manners.

The first way is to provide a specialty white water pump. This pump not only pumps the water but also dissolves the air into the water. These types of pumps are often more difficult to find and are more expensive. Also, with putting air in the pump, there is always a risk of cavitation, which causes internal damage and results in more-frequent-than-desired parts replacement.

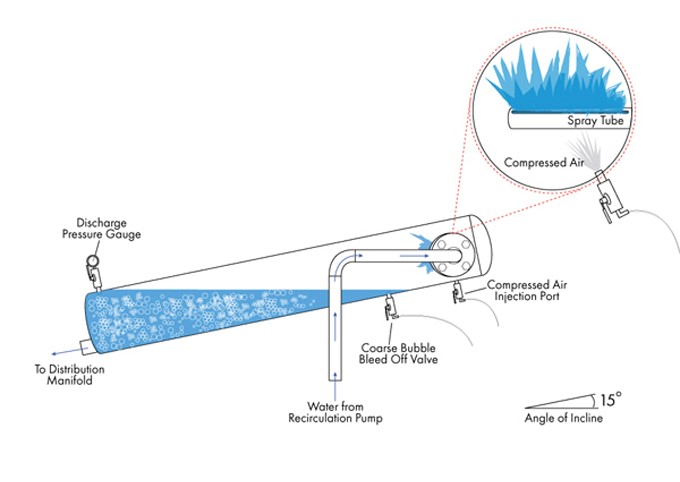

The second way is a more efficient and cost effective approach. It is to combine a standard ANSI pump with an angled air dissolving tube. In this second case, the pump doesn’t do any air dissolving – it just pumps water. No air in the pump, means very little risk for cavitation. In this way, standard ANSI recycle pumps don’t do any air dissolving – it just pumps water. That means we can provide higher solids tolerances, use stronger pump materials, operate at lower pressures, and do it at a cost much lower than possible with a specialty whitewater pump.

Angled Air Dissolving Tube

Where many DAF system manufacturers use a mechanical means to dissolve air into water, i.e. a specialty “whitewater pump,” there is a more efficient and cost-effective approach.

The air dissolving tube is where whitewater is generated. This short expansion in the recirculation piping allows clarified effluent and a small volume of compressed air to mix until saturation is achieved. The angled configuration allows for increased water and air interface so saturation occurs almost instantly.

This design works so well that often a customer will change from their specialty whitewater pump to an ANSI pump and angled air dissolving tube.

By

Ahmed Ahmed Elserwy

Water & Environmental Consultant

Ain Shames University, Faculty of Science.

References

[1] Nicholas P. Cheremisinoff, Handbook of Water and Wastewater Treatment Technologies, Butterworth-Heinemann,2002,p 62.

[2]Lawrence K. Wang, Physicochemical treatment processes, Humana Press Inc, Totowa, New Jersey 0751,2004.