Thickening [1]

Thickening of sludge is a process to increase its solids concentration and to decrease its volume by removing some of the free water. The resulting material is still fluid. Thickening is employed prior to subsequent sludge-processing steps, such as digestion and dewatering, to reduce the volumetric loading and increase the efficiency of subsequent processes.

The most commonly used thickening processes are gravity thickening, dissolved air floatation thickening, gravity belt thickening, and rotary drum thickening. Table 1 presents a comparison of these thickening processes.

Selection of a particular thickening process sometimes depends on the size of the wastewater treatment plant and the downstream train chosen. The main design variables of any thickening process are:

- Solids concentration and flow rate of the feed stream

- Chemical demand and cost if chemicals are used for conditioning

- Suspended and dissolved solids concentrations and flow rate of the clarified stream

- Solids concentration and flow rate of the thickened sludge.

Table 1 Comparison of Thickening Methods [1]

| Method | Advantages | Disadvantages |

| Gravity thickening

|

Least operation skill required | Large space required |

| Low operating costs | Odor potential | |

| Minimum power consumption | Erratic and poor solids concentration (2 to 3%) for WAS | |

| Ideal for small treatment plants | Floating solids | |

| Good for rapidly settling sludge such as WAS and chemical | ||

| Conditioning chemicals typically not required | ||

| Dissolved air flotation thickening | Provides better solids concentration (3.5 to 5%) for WAS than that of gravity thickening | Operating costs higher than for a gravity thickener |

| Require less space than a gravity thickener | Relatively high power consump | |

| Will work without chemicals or with low dosages of chemicals | Moderate operator attention requir | |

| Relatively simple equipment components | Odor potential | |

| Larger space requirements compared to other mechanical methods | ||

| Has very little storage capacity compared to a gravity thickener | ||

| Not very efficient for primary sludge | ||

| Requires polymer conditioning for higher solids capture or increased loading | ||

| Centrifugal

thickening |

Effective for thickening WAS to 4 to 6% solids concentration | High capital cost |

| Control capability for process performance | High power consumption | |

| Least odor potential and housekeeping requirements because of contained process | Requires moderate operator attention | |

| Less space required | Sophisticated maintenance requirements | |

| Requires polymer conditioning for higher solids capture | ||

| Gravity belt thickening | Effective for thickening WAS to 0.4 to 6% solids concentration | Polymer dependent |

| Control capability for process performance | Housekeeping requirements | |

| High solids capture efficiency | Odor potential | |

| Relatively low capital cost | Moderate operator attention required | |

| Relatively low power consumption | Building commonly required | |

| Rotary drum thickening | Effective for thickening WAS to 0.4 to 6% solids concentration | Polymer dependent and sensitive to polymer type |

| Less space required | Housekeeping requirements | |

| Low power consumption | Odor potential | |

| Moderate operator attention required | ||

| Building commonly required |

Centrifugal Thickening

Centrifugal thickening is the acceleration of sedimentation through the use of centrifugal force. In a gravity thickener, solids settle by gravity. In a centrifuge, force 500 to 3000 times of gravity is applied; therefore, a centrifuge acts as a highly effective gravity thickener. [2]

Centrifuges are commonly used for thickening WAS. Primary sludge is seldom thickened by centrifuges because it commonly contains abrasive material that is detrimental to a centrifuge. In addition to being very effective for thickening WAS, centrifuges have the additional advantages of less space requirement and the least odor potential and housekeeping requirements because of the contained process. However, capital cost and maintenance and power costs can be substantial. Therefore, the process is usually limited to

large treatment plants.

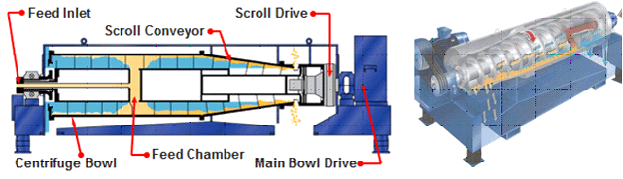

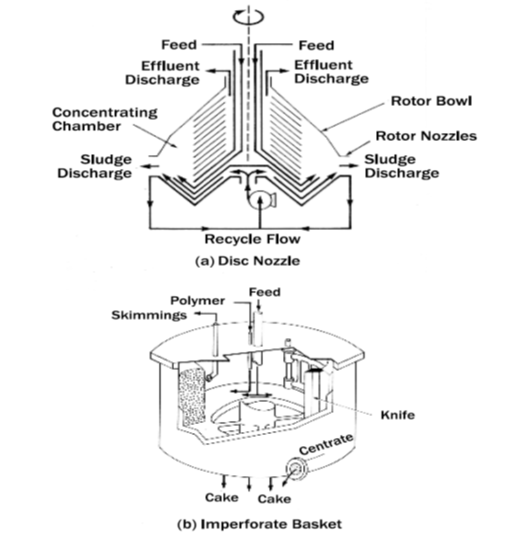

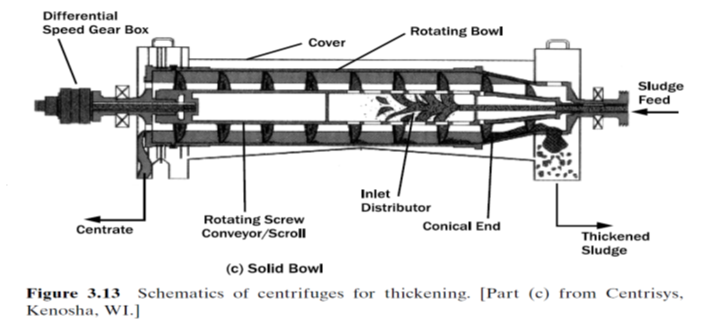

There are basically three types of centrifuges: disk nozzle, imperforate basket, and solid bowl. Figure 1 shows schematics of all three types of centrifuges. Disk nozzle centrifuges require extensive prescreening and degritting of feed sludge. They can be used on sludges with particle sizes of 400 m or less. Imperforate basket centrifuges can be used for batch operation only and not continuous feed and discharge. They suffer from high bearing wear and require significant maintenance. For these reasons, disk nozzles and imperforate basket centrifuges are being replaced by solid bowl centrifuges.

Solid bowl centrifuges (often referred to as continuous decanter scroll or helical screw conveyor centrifuges) are made in two basic configurations:

Countercurrent and concurrent. The primary differences between the two are the configuration of the conveyor (scroll) toward the liquid discharge end of the machine, and the location and confi guration of the solids discharge port.

Sludge feed enters the bowl through a concentric tube at one end of the centrifuge.

The liquid depth in the centrifuge is determined by the discharge weir elevation relative to the bowl wall. The weir is typically adjustable. As the sludge particles are exposed to the gravitational field, they start to settle out on the inner surface of the rotating bowl. The lighter liquid (centrate) pools above the sludge layer and flows toward the centrate outlet ports located at the larger end of the machine. The settled sludge particles on the inner surface of the bowl are transported by the rotating conveyor (scroll) toward the opposite end (conical section) of the bowl. The main difference between a thickening and a dewatering centrifuge is in the construction of the conveyor and the conical part of the bowl. The slope of the conical part is less in a thickening centrifuge.

Performance of a centrifuge is measured by the thickened sludge concentration (sludge cake concentration for a dewatering centrifuge) and the solids recovery (often called solids capture). [3]

Operational variables [4]

Operational variables that affect thickening include:

- Feed flow rate

- Feed sludge characteristics, such as particle size and shape, particle density, temperature, and sludge volume index

- Rotational speed of the bowl

- Differential speed of the conveyor relative to the bowl

- Depth of the liquid pool in the bowl

- Polymer conditioning, needed to improve performance

One of most important operational parameters of centrifuges is the factor of separation F, which demonstrates how centrifugal forces are stronger than sedimentation forces by the following equation:

F=a/g , a=wr or F=r (n/g)

Where:

F =separation factor

a =speed of centrifugal force, m/s2

g = speed of sedimentation force, m/ s2

w = angle speed of bowl (rotor), min−1

r = inside radius of bowl, m

n = speed of bowl (rotor) rotation, min−1

Increasing the speed of bowl (rotor) rotation allows an increase in the factor of separation. However, the high bowl rotation speed can decrease the sludge particle sizes, increase the polymer demand, and decrease the effectiveness of flocculation. Therefore, centrifuges typically operate at speeds between 1500 and 2500 rpm, with the factor of separation between 600 and 1600. At the lower values of factor of separation, thickened sludge concentration and solids recovery values are lower.

By

Ahmed Ahmed Elserwy

Water & Environmental Consultant

Technical Manager Louts for Water Treatment

References

[1] Wastewater sludge processing / Izrail S. Turovskiy, P. K. Mathai, John Wiley & Sons, Inc., Hoboken, New Jersey,2006, p 81.

[2] L. K. Wang, Y. T. Hung, and N. S. Shammas (eds.), Physicochemical Treatment Processes. Humana Press, Totowa, NJ (2005) ,p 684.

[3] Metcalf & Eddy, Tchobanoglous, G., Burton, F. L., Stensel, H. D. “Wastewater engineering: treatment and reuse/Metcalf & Eddy, Inc.”, Tata McGraw-Hill, 2003.

[4] Wastewater sludge processing / Izrail S. Turovskiy, P. K. Mathai, John Wiley & Sons, Inc., Hoboken, New Jersey,2006, p 96.