- Introduction

Quality Control and Quality Assurance (QC/QA) are two important, if not critical, parts of meeting Data Quality Standards (DQS).

The term quality assurance describes the system of activities intended to provide evidence to the producer or user of a product or service that it meets predefined standards of quality with a stated level of confidence. It consists of related but independent activities: quality control and quality assessment. Quality control describes those activities and procedures used internally (within a lab or in the field) to produce consistent and reliable data. Quality assessment deals with activities to independently evaluate data quality, after a value is produced by the analysis method used [1].

2. Quality Control Measures in Water Laboratories [2].

Quality Control is the daily functions carried out during the collection and analysis of samples to help produce accurate and precise results; Examples: Proper cleaning of sampling equipment and bottles, calibration of testing instruments, analyzing blanks, replicates, and spikes.

Quality Control Measures is practices that done in laboratory to control all aspects of quality in laboratory for detection and prevention of errors.the most important measures are:

- Laboratory Cleanliness

- Personnel Training

- Equipment Maintenance

- Analytical Reagents

- Reagent Water Quality

- Labware Cleaning

Laboratory Cleanliness

The laboratory is to be kept clean and organized at all times. The room temperature should be kept as constant as possible. Appropriate actions are taken to maintain air quality.

Personnel Training

Training for all personnel involved with laboratory analysis must be documented showing that they are capable of meeting the Data Quality Objectives (DQOs). Initial performance can be demonstrated through the use of Quality Control Standards and internal or external split samples. Continuing training on a regular basis should be provided to help maintain competence of analytical skills.

Equipment Maintenance

Files are maintained for each piece of laboratory equipment. These files contain the operating manual, a preventative maintenance schedule, and a record of any maintenance and repairs performed. The maintenance and repair record is to contain the following information: nature of problem, date of repair, maintenance/repair performed, person performing maintenance/repair, and cost, if any. These records will help the laboratory personnel determine if results were affected by an instrument malfunction. As part of the routine equipment maintenance, analytical balances are serviced annually and dissolved oxygen and ammonia probe membranes may need to be replaced every two to four weeks unless readings become unstable, then these membranes are replaced immediately.

Analytical Reagents

All chemicals and reagents used in the laboratory are analytical grade or better (such as ACS). Upon receipt in the laboratory, each chemical is marked in permanent ink with date received on the label and when opened for the first time. Any reagents or solutions prepared in the laboratory must have a label with the date prepared and by whom. Because labels are replaced, this information is also recorded in a permanent record as part of the three-year record keeping requirement. Chemicals and reagents are stored away from direct sunlight and, if necessary, refrigerated to prevent deterioration. If refridgerated, chemicals should be brought to room temperature before aliquots are measured. Stock chemicals and reagents are transferred to a clean container prior to weighing, pipetting, etc., to prevent contamination. All solutions or reagents are discarded and ordered or prepared fresh after being opened one year unless the analytical method specifies a shorter time period for replacement. All chemicals are stored in a safe manner and segregated by hazard type. Those hazard types commonly found in a wastewater laboratory are:

Health – identified with Blue on the label

Reactive – identified with Yellow on the label

Corrosive – identified with White on the label

Flammable – identified with Red on the label

General – identified with Green or Orange on the label.

All flammable chemicals are to be stored in fireproof cabinet and strong acids and bases are to be stored separately from each other. In the event, a chemical has stripe marks on the colored hazard code label; this is a warning not to store it with chemicals of the same colored hazard code. An example being a chemical with a striped yellow hazard code label is to be stored separately from chemicals with a yellow hazard code.

A Material Safety Data Sheet (MSDS) is to be on file and accessible for all purchased chemicals and reagents used by the laboratory personnel.

Reagent Water Quality

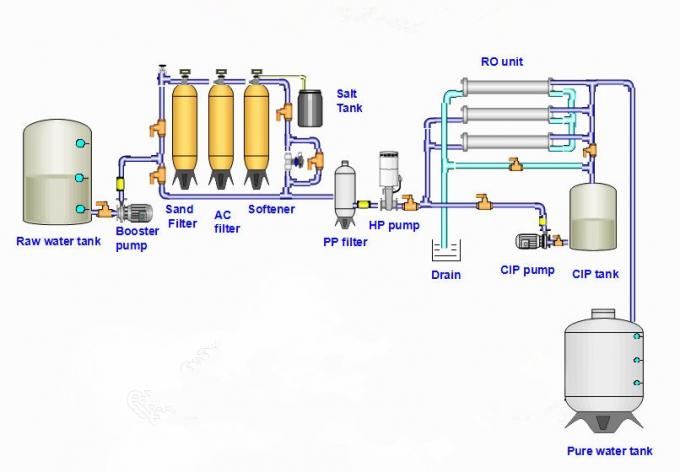

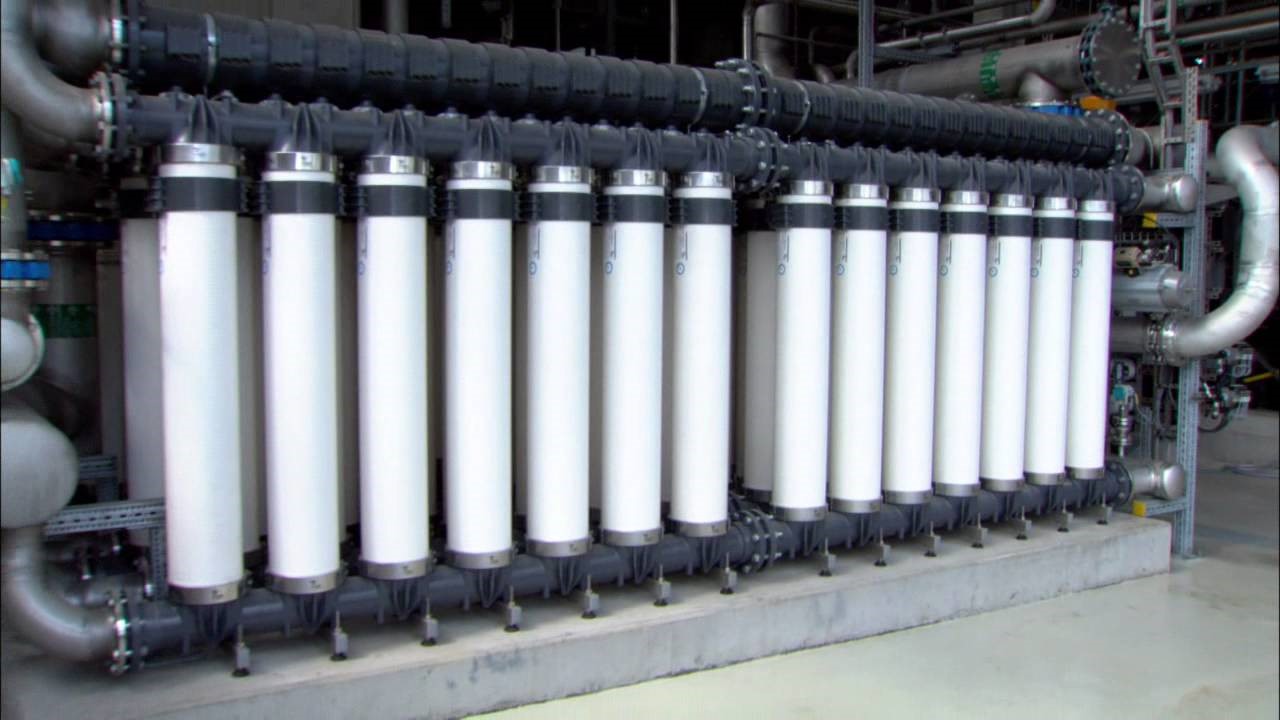

Reagent grade water used for chemical analysis is produced in the laboratory using distillation, reverse osmosis or ion exchange and meets the following specifications:

Resistivity, megohm-cm at 25 degrees C = >1

Conductivity, mho/cm at 25 degrees C = <1

SiO2, mg/L = < 0.1

In addition, if the reagent grade water is used for bacteriological analysis, it must meet the following additional specifications:

pH = 5.5 – 7.5 S.U.

Total organic carbon = < 1.0 mg/L

Heavy metals, single (Cd, Cr, Cu, Ni, Pb, and Zn) = < 0.05 mg/L

Heavy metals, total = < 0.10 mg

Ammonia/organic nitrogen = < 0.10 mg/L

Total chlorine residual = < 0.01 mg/L

Only freshly prepared reagent water is used for ammonia analysis to prevent contamination from ammonia in the air. Dilution water for BOD5 analysis is stored in light shielded containers, sealed in such a manner to allow a free exchange of air without contamination. (Examples: cotton plugs, loose fitting container lids) Reagent water for other laboratory tests is stored in tightly stoppered glass containers or withdrawn fresh from the water purification unit.

Labware Cleaning

After each use, glassware and plastic ware is washed with detergent, rinsed with tap water followed by a thorough rinse with reagent water. After drying, it is stored in a cabinet. There are appropriate glassware cleaning procedures for specific tests, for example, glassware used for total phosphorus analysis is washed in non-phosphate detergent, acid-washed after each use and kept separate from other laboratory glassware. (The best choice would be using a detergent that is both ammonia- and phosphate-free, thus eliminating having different detergents for different procedures.) Care must be taken to store BOD5 bottles dry to prevent the growth of bacteria or algae in the bottle. The BOD5 siphon tubing should be cleaned monthly with dilute bleach solution (25 mL bleach / Liter of reagent water) inspected daily for growth and replaced or cleaned more often if any growth is observed. All containers used to store reagent water are inspected for growth or other signs of contamination prior to withdrawing water from them. If growth or signs of contamination are observed, the reagent water is discarded and the container cleaned with dilute hydrochloric acid followed by rinsing with tap water and a thorough rinsing with reagent water.

Instrument Calibration

The pH meter, dissolved oxygen meter, and ammonia ion selective electrode are calibrated each day they are used. If they are used throughout the day, a calibration check is repeated if more than two hours has passed following the initial calibration. Temperature of incubators and refrigerators are measured on thermometers with their bulbs immersed in liquid, see note below. Each day the temperature of the incubators and refrigerators are recorded on a log sheet taped to the equipment or in a logbook. The temperatures of the drying oven(s), muffle furnace and bacteria incubation baths are recorded on the bench sheet or in a logbook when these pieces of laboratory equipment are used for analysis. The temperature of the autoclave is read using a maximum reading thermometer and this reading recorded on the bench sheet or in a logbook. When equipment temperatures read outside the required range, the equipment thermostats are adjusted and this adjustment is recorded on the log sheets, bench sheets, or in the logbook.

Thermometers used in the laboratory are calibrated annually against a thermometer traceable to an NIST (National Institute of Standards and Technology) certified thermometer. The NIST thermometer must have been certified within the past five years. Any correction factors associated with the NIST certified thermometer are recorded on the thermometer calibration log sheet and any correction factors associated with the laboratory thermometer(s) are noted on a tag attached to the thermometer. If the liquid column in the thermometer becomes separated, the thermometer in no longer accurate and must be replaced. An alternative to calibrating laboratory thermometers is to purchase factory certified thermometers traceable to NIST thermometers. These thermometers are sealed in a clear container with the bulb in a medium appropriate to the equipment temperature being measured. Each thermometer comes with a unique serial number, a certificate of NIST traceability, and the required re-certification and/or expiration date.

Note: Thermometers are calibrated for total immersion or partial immersion. Those calibrated for partial immersion must be immersed only to the depth of the etched circle around the stem of the thermometer just below the thermometer scale readings. Those calibrated for total immersion must be completely immersed in the matrix being measured.

Analytical balances are zeroed daily and the calibration checked at least monthly. One of these weights is in the milligram and one in the gram range. Documentation of the daily zeroing and monthly weight checks are recorded in a logbook. If the balance readings are not within 0.5 mg of the certified weight, a certified technician must service the balance.

All records relating to instrument calibrations, thermometer calibrations, and temperature logs must be retained a minimum of three years.

Routine Quality Assurance in Water Laboratories

Quality assurance in routine analysis includes both internal laboratory quality control and all internal or external measures that are taken preventatively or as a result of alarming results. Routine refers here not only to the analyses, the quality of which should continue to be guaranteed, but also to the quality assurance measures that become a natural and routine part of the analysis.

Quality Assurance System [3]

Following the ISO standards, the quality assurance system of an analytical laboratory should consist of:

_ The responsibility and accountability of the management,

_ The principles of the quality system, including:

- the structure and responsibility of laboratory management,

- an internal quality auditing system,

- quality-related cost considerations,

- quality in procurement, purchasing,

- quality of contracts with clients and subcontractors,

- task management, scheduling and tracing of tasks and contracts,

_ Quality of the analytical process, including:

- quality of the laboratory, installations, and equipment,

- material control and traceability,

- validation of analytical methods,

- quality control of the analytical process,

- quality control of the analytical results,

- quality and quality control of reporting and archiving results,

_ control of measuring and test equipment, inspections, and calibration of instruments,

_ maintenance,

_ handling and disposal of wastes; environmental protection,

_ handling of internal analytical quality problems,

_ handling of externally indicated analytical quality problems,

_ handling of customer complaints,

_ corrective actions,

_ quality records and documentation,

_ personnel qualification and training,

_ confidentiality and security (professional secrecy),

_ use of statistical methods.

All topics mentioned above must be elaborated in a structured quality manual of the laboratory [4]. All related actions and procedures have to be described as a so-called standard operating procedure (SOP). When a given acknowledged standard is followed exactly, the description may be reduced to the citation of this standard.

In all other cases, the operating procedures must be described in detail. The quality manual should be maintained and up-to-date.

Quality assurance in analysis phase

Quality assurance in analysis Phase includes all the components of analysis:

_ the laboratory from the perspective of planning and equipping,

_ the equipment,

_ the personnel,

_ the analytical process:

– spectrum of the process,

– requirements (including quality assurance requirements),

_ the samples,

_ the reagents,

_ the “outcome”, quality control and documentation,

_ the inclusion in an external quality assurance system.

By

Ahmed Ahmed Elserwy

Water & Environmental Consultant

Ain Shames University, Faculty of Science

References

[1] Saad Hassan , Quality Control/Quality Assurance Manual for Water Sampling and Analysis, Water and Wastewater Management Programme GTZ Project No. 06.2006.3 ,July 2008.

[2].Quality assurance manual, Indiana water laboratories, July 2006.

[3] W. Funk, V. Dammann, G. Donnevert ,Quality Assurance in Analytical Chemistry, WILEY-VCH Verlag GmbH & Co. KGaA,Weinheim, Germany,2007.

[4] ISO Guide 49: Guidelines for the Development of a Quality Manual for Testing Laboratories.