Aerobic Treatment with Biofilm Systems

Biofilms

Biofilms are small ecosystems usually consisting of three layers of differing thickness,

which change in thickness and composition with location and over time (Meyer-Reil 1996). In the first phase of colonization, macromolecules are adsorbed at clean solid surfaces (proteins, polysaccharides, lignin; Wingender and Flemming 1999), because they are transported from the bulk liquid to the solid surface faster than the microorganisms are. As a consequence of this adsorption, the coverage of the solid surface with water is reduced. During the second phase, microbial cells attach to this prepared surface. Frequently, they do not form closed layers of uniform thickness, rather they form small attached colonies, which may spread by growth and further attachment. Usually, these cells are supplied with substrate and oxygen and are able to grow at their maximum rate. During this process, they produce organic molecules, which diffuse through the cell wall and to extracellular polymeric substances (EPS) catalyzed by exoenzymes. These EPS molecules are necessary for the formation of a stable biofilm (Wingener and Flemming 1999). In the third phase, the biofilm may consist of bacteria and EPS, the thickness of which is a function of growth rate and depends on the stability of the biofilm and the shear stress of the flowing water (Van Loodsrecht et al. 1995). At lower shear stresses ,eukaryotic organisms (protozoa, insects, their eggs and larvae) typically establish themselves. All these organisms live in a community. Materials such as substrates and oxygen are transported into the biofilm by diffusion and convection and the products are transported out of the biofilm.

Oxygen may reach only into the exterior part of the biofilm, resulting in a growth of aerobic microorganisms such as nitrifying bacteria and protozoa. Nitrate and nitrite produced in this layer are reduced by anoxic metabolism within a middle layer, resulting in an anaerobic interior layer directly at the solid surface, where acetic acid and sulfate may be reduced (Marshall and Blainey 1991; Fig.1).

Heterogeneous biofilms grow on the sides of ships and on buildings near the water’s edge, inside human and animal mouths and within inner organs. They frequently cause damage to these surfaces (biocorrosion) and must be removed. In the area of environmental biotechnology, however, they can be utilized to advantage in certain bioreactors, such as:

- trickling filters,

- submerged, aerated fixed bed reactors,

- rotating disc reactors.

The formation of biofilms is a requirement for their effectiveness.

Fig.1 Biofilm model (according to Marshall and Blainey 1991).

Trickling Filters

A trickling filter consists of a layer of solid particles or bundles of synthetic material inside a cylindrical (Fig..2) or prismoid container. Wastewater must be distributed uniformly at the top of the fixed bed – frequently by a rotating system of two or four horizontal tubes equipped with many nozzles.

To compensate for the fact that the area of a circular section of the reactor increases with distance from the center, the distance between nozzles must decrease the further they are away from the center in order to have an even distribution of water over the surface. Furthermore, the changes in available pressure in the rotating tubes must be considered as a function of the flow rate. Uniform distribution of the wastewater and uniform packing of the reactor with solid substances are of high importance for a high loading and removal rate. It is critical to ensure that two conditions are met:

The downward flowing liquid films must be in direct contact with the biofilm (i.e. the biofilm has to be trickled over all places and at all times) and must be in contact with the upward or downward flowing air (i.e. the trickling filter should not be flooded at any location or time).

The wastewater must be practically free of solids. It is absolutely necessary that the wastewater passes a primary settler under controlled conditions which is never overloaded.

We distinguish between:

Natural aeration as a result of density differences between the air saturated with moisture inside the trickling filter and the air outside the trickling filter, and

Forced aeration by a ventilator at the top of the trickling filter. In this case, the reactor may have a height of up to 12 m and is filled with packages of synthetic supporting material.

Fig. 2 Trickling filter, BIO-NET, Norddeutsche

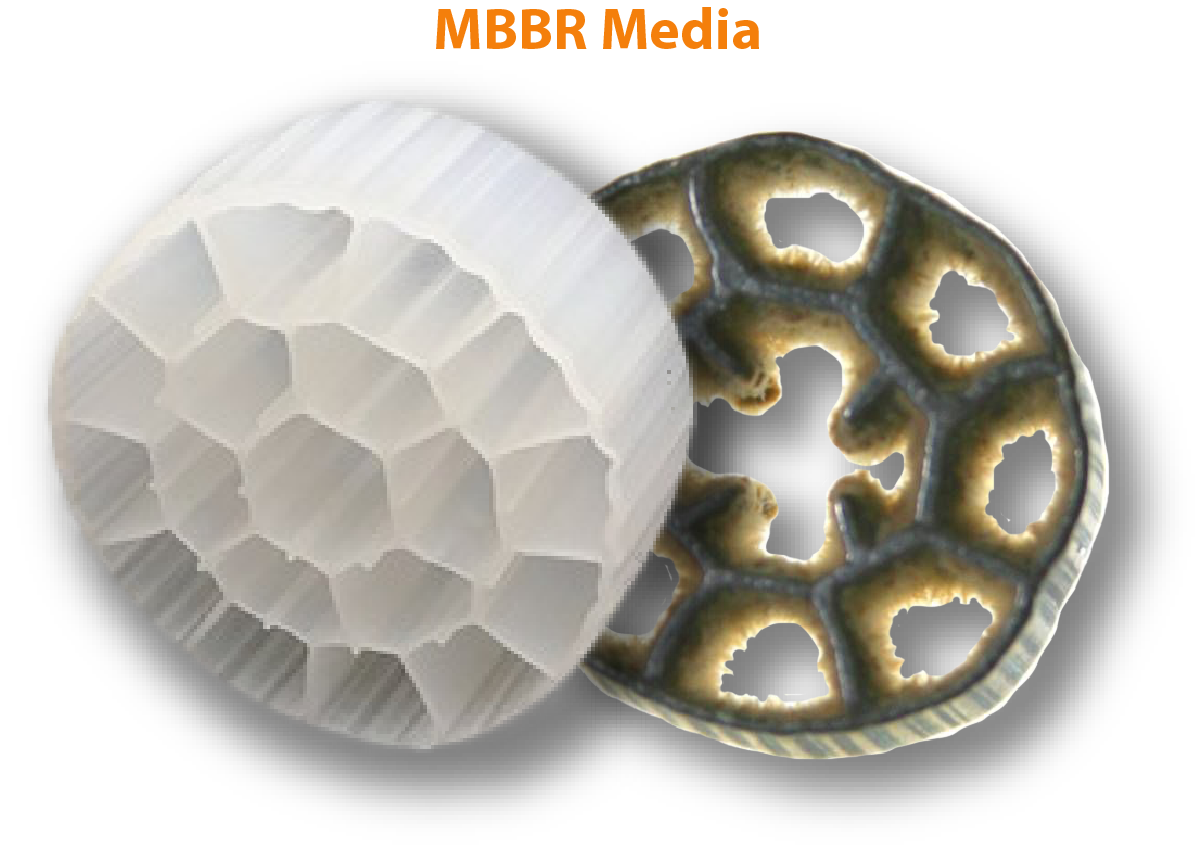

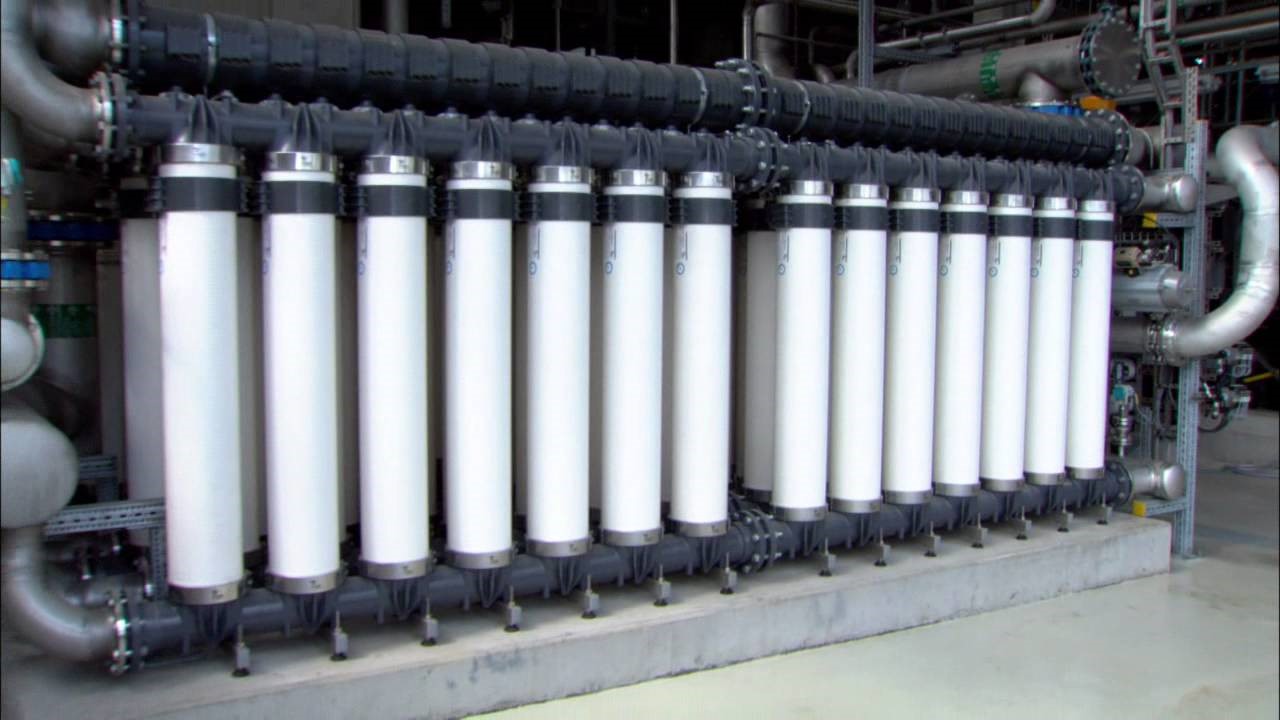

Submerged and Aerated Fixed Bed Reactors

In cases of high hydraulic loading, the trickling filter may be operated as a flooded bed and the pressure differential needed for the downwards flow increases. The level of wastewater necessary to overcome the flow resistance depends on the form of the substance used as support material and the thickness of the biofilm. Aerobic fixed beds must be aerated near the bottom, producing a two-phase flow in a three phase system with an upwards air flow. As a result of friction forces, water is transported upwards in the center of the reactor and flows downwards near its walls.

Biomass is attached at the surface of the support material and is also suspended as flocs. It is not easy to avoid blockages in regions of biofilms with a higher thickness and a lower local flow rate. The fixed bed must be cleaned from time to time by considerably increasing the wastewater flow rate.

Synthetic support materials such as BIOPAC (ENVICON, Germany) have been used successfully, especially where nitrifying bacteria with lower growth rates must be immobilized (Fig..3).

In contrast to fixed beds with solid particles, the flow of water and air are more easily controlled and blockages can be avoided in reactors with suspended particles.

In contrast to trickling filters, their air flow rates can be adjusted to match the loading of organics and ammonia. The specific surface area can be increased to up to 400 m2 m–3 (Schulz and Menningmann 1999). Using membrane-type tubular aerators, fine bubbles are produced and the mass transfer rate is increased remarkably.

The suspended biological sludge detaches from the surfaces as a result of the friction forces of the flow and is conveyed to the secondary settler. Obviously, blockages do not occur.

Fig. 3 Submerged aerated fixed bed reactor

(a) and BIOPAC (b)(ENVIRON, Germany; Schulz and Menningmann 1999).

Rotating Disc Reactors

In rotating disc reactors (RDR), the principle behind the intense transport of substrates and oxygen to the biofilm is different. In trickling filters and fixed bed reactors, water and air are moved; here, the support material with the biofilm are moved. In rotating disc reactors, circular plates with diameters of 1–2 m are fitted to a horizontal shaft with a spacing of a few centimeters. The system of parallel plates is submerged nearly halfway in a cylindrical tank through which wastewater flows. The packet of plates rotates at a speed of 0.5–5.0 rpm. Bacteria grow on both surfaces of the circular discs. During the portion of the rotation where the biofilm travels through the air, wastewater drips down and oxygen is taken up by convection and diffusion. Parts of the biofilm rinse off from the discs from time to time.

Larger pieces settle in the tank and must be removed as surplus sludge, while smaller parts are suspended and involved in aerobic substrate degradation and further growth (carbon removal and nitrification).

By

Ahmed Ahmed Elserwy

Water & Environmental Consultant

Ain Shames University, Faculty of Science

References

- Marshall, K.C.; Blainey, B. 1991, Role of bacterial adhesion in biofilm formation and bio corrosion, in: Biofouling and Biocorrosion in Industrial Water Systems, ed. Flemming, H.-C.; Geesey, G.G., Springer-Verlag, Heidelberg, p. 8–45.

- Metcalf, Eddy 1991, Wastewater Engineering: Treatment, Disposal, And Reuse, 3rd edn, McGraw-Hill, New York.

- Meyer-Reil, L.-A. 1996, ضkologie mikrobieller Biofilme, in: ضkologie der Abwasserorganismen, ed. Lemmer, H.; Griebe, T.; Flemming, H.-C., Springer-Verlag, Berlin, p. 24–42.

- Wingender, J.; Flemming, H.-C. 1999, Autoaggregation of microorganisms: flocs and biofilms, in: Environmental Processes I, (Biotechnology, Vol. 11a), ed. J. Winter, Wiley-VCH, Weinheim, p. 65–83.