Introduction

Only 1 percent of the earth’s water is liquid freshwater; 97 percent of available water resources are contaminated by salt. This makes desalination an essential component of efforts to address water shortages, especially in densely populated coastal regions. Egypt faces nowadays severe challenges to our ability to meet our future water needs, So we as a nation will need to make additional water resources available to all segments of our nation’s and provide additional water resources at a cost and in a manner that supports urban, rural and agricultural prosperity and environmental protection; Meeting these challenges may lead us to use saline water for a greater national focus on water conservation.

Desalination Definition

Desalination is a process that removes salts and other dissolved solids from brackish Water or seawater.

Brackish water and seawater

Brackish water is saltier than fresh water, but not as salty as seawater. Brackish water usually has a salt concentration between 5 and 20 parts per thousand (ppt) and seawater generally has a concentration of salt greater than 20 ppt. Brackish waters may also be found in aquifers.

Water type and Total Dissolved Solid:

| TDS(mg/l) | Water type |

| 0-1000 | Sweet waters |

| 1000-5000 | Brackish waters |

| 5000-10000 | Moderately saline waters |

| 10000-30000 | Severely saline waters |

| More than 30000 | Seawater |

Significance of Desalination

- Desalination technologies will contribute significantly to ensuring a safe, sustainable, Affordable, and adequate water supply for Egypt.

- Provide safe water: A safe water supply is one that meets all drinking water standards, meets all standards for use by agricultural and industrial interests, and that strives to move toward greater water security during drought, natural disasters, transport.

- Ensure the sustainability of the nation’s water supply: A sustainable water supply is one that meets today’s needs without jeopardizing the ability to meet the needs of future generations.

- Keep water affordable: An affordable water supply is one that provides water to the nation’s future citizenry at rates comparable to that of today.

- Ensure adequate supplies: An adequate water supply is one that guarantees local and regional availability of water.

Desalination techniques:

1. Distillation:

- Multi-stage flash distillation (MSF)

- Multiple-effect evaporator (MED|ME)

- Vapor-compression evaporation (VC)

2. Membrane processes:

- Electrodialysis reversal (EDR)

- Reverse osmosis (RO)

1.1. Multi-stage flash distillation

Multi-stage flash distillation (MSF) is a water desalination process that distills sea water by flashing a portion of the water into steam in multiple stages of what are essentially countercurrent heat exchangers. Multi-stage flash distillation plants produce [64%] percent of all desalinated water in the world, although a different type of desalinators, Reverse osmosis plants, are more numerous.

1.1.1. Principle:

The plant has a series of spaces called stages, each containing a heat exchanger and a condensate collector. The sequence has a cold end and a hot end while intermediate stages have intermediate temperatures. The stages have different pressures corresponding to the boiling points of water at the stage temperatures. After the hot end there is a container called the brine heater. When the plant is operating in steady state, feed water at the cold inlet temperature flows, or is pumped, through the heat exchangers in the stages and warms up. When it reaches the brine heater it already has nearly the maximum temperature. In the heater, an amount of additional heat is added. After the heater, the water flows through valves back into the stages which have ever lower pressure and temperature. As it flows back through the stages the water is now called brine, to distinguish it from the inlet water. In each stage, as the brine enters, its temperature is above the boiling point at the pressure of the stage, and a small fraction of the brine water boils (“flashes”) to steam thereby reducing the temperature until equilibrium is reached. The resulting steam is a little hotter than the feed water in the heat exchanger. The steam cools and condenses against the heat exchanger tubes, thereby heating the feed water as described earlier.

Fig.1 The schematic representation for MSF technique

1.2. Multiple-effect distillation (MED)

Multiple-effect distillation is a distillation process often used for sea water desalination. It consists of multiple stages or “effects”. In each stage the feed water is heated by steam in tubes. Some of the water evaporates, and this steam flows into the tubes of the next stage, heating and evaporating more water. Each stage essentially reuses the energy from the previous stage.

The tubes can be submerged in the feed water, but more typically the feed water is sprayed on the top of a bank of horizontal tubes, and then drips from tube to tube until it is collected at the bottom of the stage.

1.2.1. Principle:

The plant can be seen as a sequence of closed spaces separated by tube walls, with a heat source in one end and a heat sink in the other end. Each space consists of two communicating subspaces, the exterior of the tubes of stage n and the interior of the tubes in stage n+1. Each space has a lower temperature and pressure than the previous space, and the tube walls have intermediate temperatures between the temperatures of the fluids on each side. The pressure in a space cannot be in equilibrium with the temperatures of the walls of both subspaces. It has an intermediate pressure. Then the pressure is too low or the temperature too high in the first subspace and the water evaporates. In the second subspace, the pressure is too high or the temperature too low and the vapor condenses. This carries evaporation energy from the warmer first subspace to the colder second subspace. At the second subspace the energy flows by conduction through the tube walls to the colder next space.

Fig.2 The schematic representation for MED technique

1.3. Vapor-compression desalination

The VC operates mainly at a small scale, on small locations. The main mechanism is similar to MED except that it is based on compression of the vapor generated by evaporating water to a higher pressure, Which allows reuse of the vapor for supplying heat for the evaporating process.

Membrane desalination:

2.1. Electrodialysis reversal

It is an electro dialysis reversal water desalination membrane process that has been commercially used since the early 1960s. An electric current migrates dissolved salt ions, including fluorides, nitrates and sulfates, through an electrodialysis stack consisting of alternating layers of cationic and anionic ion exchange membranes. Periodically, the direction of ion flow is reversed by reversing the polarity applied electric current.

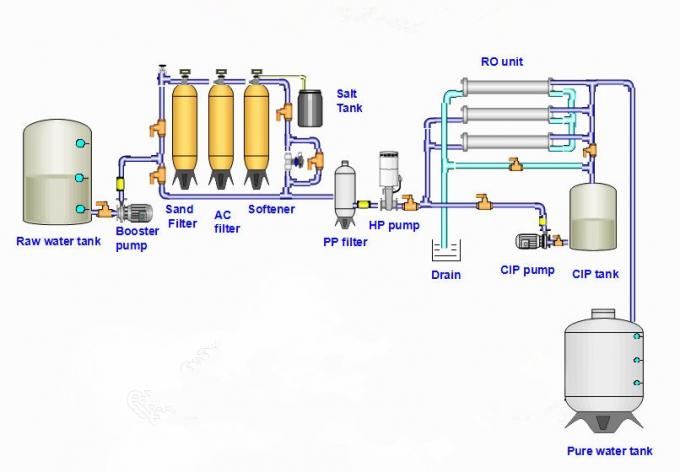

2.2. Reverse osmosis

Reverse osmosis (RO) is a filtration method that removes many types of large molecules and ions from solutions by applying pressure to the solution when it is on one side of a selective membrane. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side. To be “selective,” this membrane should not allow large molecules or ions through the pores (holes), but should allow smaller components of the solution (such as the solvent) to pass freely.

Fig.3 The schematic representation for RO technique

Advantages and disadvantages of desalination techniques:

| Desalination type | Usage | Advantages | Disadvantages |

| Multi-stage flash distillation (MSF)

Desalination process that distills seawater by flashing a portion of the water into steam in multiple stages of what are essentially regenerative heat exchangers. |

Accounts for 85% of all desalinated water; used since early 1950s | MSF plants, especially large ones, produce a lot of waste heat and can therefore often be paired with cogeneration | High operating costs when waste heat is not available for distillation. High rates of corrosion |

| Multiple-effect evaporator (MED|ME)

Using the heat from steam to evaporate water. In a multiple-effect evaporator, water is boiled in a sequence of vessels, each held at a lower pressure than the last. |

Widely used, since 1845 | High efficiency, while relatively inexpensive | A large heating area is required |

| Vapor-compression evaporation (VC)

Evaporation method by which a blower, compressor or jet ejector is used to compress, and thus, increase the temperature of the vapor produced. |

Mainly used for wastewater recovery | Technique copes well with high salt content in water | – |

| Evaporation/condensation

Evaporation of seawater or brackish water and consecutive condensation of the generated humid air, mostly at ambient pressure. |

Widely used | Easiest method of distillation | Time-consuming and inefficient in comparison to other techniques |

| Electrodialysis reversal (EDR)

Electrochemical separation process that removes ions and other charged species from water and other fluids. |

Widely used, since early 1960s | Long membrane lifetime and high efficiency (up to 94% water recovery, usually around 80%) | High capital and operational costs |

| Reverse osmosis (RO)

Separation process that uses pressure to force a solvent through a membrane that retains the solute on one side and allows the pure solvent to pass to the other side. |

Widely used, first plant installed in Saudi Arabia in 1979 | In water purification, effectively removes all types of contaminants to some extent | Requires more pretreatment of the seawater and more maintenance than MSF plants |

| Nanofiltration (NF)

Nanofiltration membranes have a pore size in the order of nanometers and are increasingly being used for water desalination. |

Emerging technology | Very high efficiency | High capital cost, unknown lifetime of membrane, no large-scale plant built yet |

| Membrane distillation (MD)

In membrane distillation, the driving force for desalination is the difference in vapor pressure of water across the membrane, rather than total pressure. |

Widely used | Low energy consumption, low fouling | – |

Considerations in water desalination:

1. Cogeneration:

Cogeneration is the process of using excess heat from power production to accomplish another task. Theoretically any form of energy production could be used. However, the majority of desalination plants use either fossil fuels or nuclear power as their source of energy. Most plants is located in the Middle East or North Africa, due to their petroleum resources.

2. Economics:

A number of factors determine the capital and operating costs for desalination: capacity and type of facility, location, feed water, labor, energy, financing, and concentrate disposal

Desalination stills now control pressure, temperature and brine concentrations to optimize the water extraction efficiency. In places far from the sea, like New Delhi, or in high places, like Mexico City, high transport costs would add to the high desalination costs. One needs to lift the water by 2,000 meters (6,600 ft), or transport it over more than 1,600 kilometers (990 mi) to get transport costs equal to the desalination costs. Thus, it may be more economical to transport fresh water from somewhere else than to desalinate it. Desalinated water is also expensive in places that are both somewhat far from the sea and somewhat high, such as Riyadh .Israel is now desalinating water at a cost of US$0.53 per cubic meter.[17] Singapore is desalinating water for US$0.49 per cubic meter

3. Environmental:

One of the main environmental considerations of ocean water desalination plants is the impact of the open ocean water intakes, especially when co-located with plants. These intakes are no longer viable without reducing mortality, by ninety percent, of the life in the ocean; the plankton, fish eggs. Other environmental concerns include air pollution and greenhouse gas emissions from the power plants. To limit the environmental impact of returning the brine to the ocean, it can be diluted with another stream of water entering the ocean. Discharges of brine into sea water have the potential to harm ecosystems, especially marine environments in regions with low turbidity and high evaporation that already have elevated salinity. Examples of such locations are the Persian Gulf, the Red Sea and The UAE, Qatar, Bahrain, Saudi Arabia, Kuwait and Iran have 120 desalination plants between them. These plants flush nearly 24 tons of chlorine, 65 tons of algae-harming antiscalants used to descale pipes, and around 300kg of copper into the Persian Gulf every day.

Conclusion:

Desalination process provides safe water and ensures the sustainability of the nation’s water supply. Egypt should do their best to use our sources such as solar energy and wind to use it as an inexpensive techniques for seawater desalination.

By

Amal Sayed Moustafa Elsonbaty

Environmental Researcher